The products

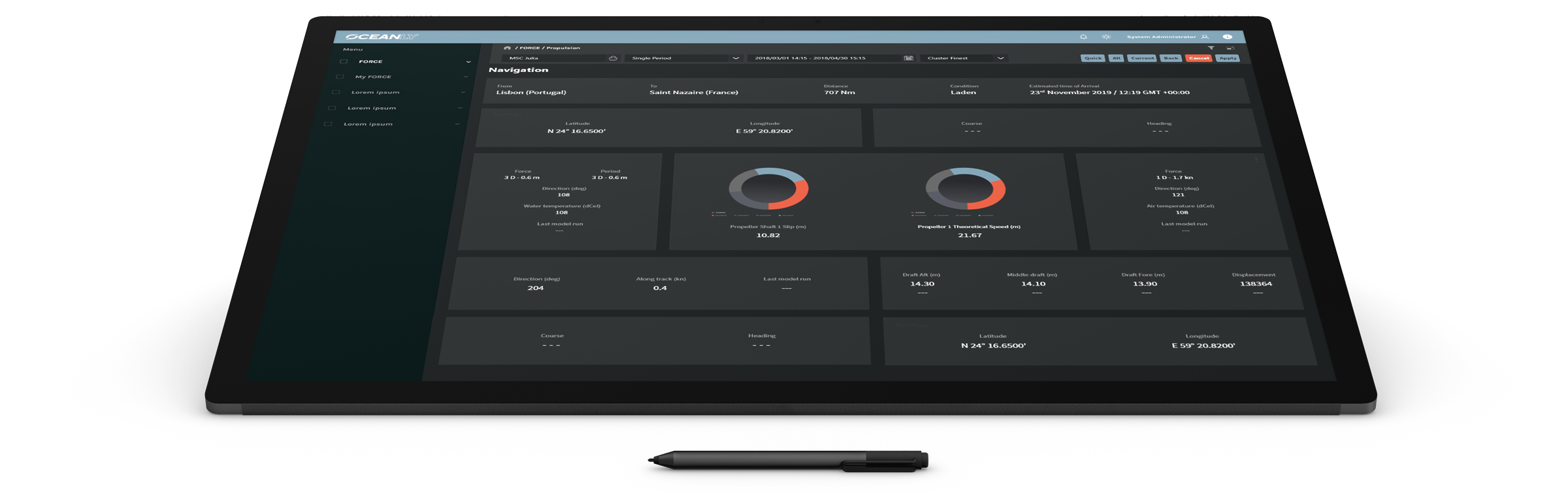

Oceanly Performance offers a cloud-based and flexible platform that forms

the very foundation of your decarbonization undertaking, and your path towards a fleet

remote monitoring solution.

Data Collector

Our Data Collector (DC) can connect to any data source on board your vessels, using standard (NMEA MODBUS OPC, etc.) or proprietary protocols. The main data sources are automation and, navigation systems, on-board sensor systems like inclinometers, torque meters, flow meters, anemometers, etc. Other systems such as ECDIS, Gyro, Echo Sounder, etc., or other additional databases or data loggers (if any) can also be integrated. The DC not only collects data based on predefined (adjustable) intervals but also has computational and interpolation capabilities. The data collected will serve the purpose of real-time monitoring but also the possibility to analyze historical data.

There are several benefits using sensor data for vessel reporting instead of manual input:

-

01Increased accuracySensor data is objective and will provide a more accurate representation of what is happening on a vessel. This is particularly useful for tracking things like fuel consumption, engine performance, and cargo levels.

-

02Reduced errors:Using sensor data eliminates the potential for errors that can occur when manual input is used. This helps to improve the accuracy of reports and reduces the risk of incorrect information being used to make decisions.

-

03Increased efficiencyCollecting and inputting data manually can be time-consuming and labour-intensive. Using sensor data allows for automated collection and reporting, which saves time and resources.

-

04Better decision-makingAccurate and up-to-date data is essential for making informed decisions. By using sensor data, vessel operators will be able to make more accurate and timely decisions based on real-time information.

-

05Real-time detectionMonitoring the vessel in real-time will allow the crew to continuously monitor and detect potential hazards or issues on a ship as they occur. This can include monitoring the vessel's systems, such as navigation and propulsion, as well as external factors such as weather and sea conditions. Real-time detection can be achieved using sensors, cameras, and other monitoring equipment, which provide data that can be analysed and used to detect potential issues and alert the crew to take action.

-

06Better ComplianceSensor data which are used to monitor a vessel’s compliance with regulations, will reduce the risk of fines and penalties

Vessel reporting

VRT is a tool for manual data collection (Departure-, Arrival-, Noon-reports etc) but does also enrich the database with relevant information (Bunkering, Weather Condition, Voyage information etc). VRT can also be linked to Automatic data collection feeding the reports with automatic inputs.

VRT is important for Emission Regulation Data Collection such as IMO DCS, EU MRV and UK MRV, but also for the Time Charter Party module that enables the user to monitor and create reports according to Charter Party agreements.

Trim Optimization

There are several benefits using the Oceanly trim optimization:

-

01Increased fuel efficiencyProper trim reduces drag and improves a ship's hydrodynamic performance, which results in reduced fuel consumption and lower operating costs.

-

02Enhanced stabilityTrim optimization helps to improve a ship's stability and reduces the risk of capsizing or rolling in rough seas.

-

03Improved manoeuvrabilityBy adjusting the trim, a ship can be made more agile and easier to handle, which is particularly useful in tight or crowded waterways.

-

04Enhanced safetyProper trim can help to reduce the risk of accidents and improve the safety of the crew and passengers.

-

05Increased payload capacityBy optimizing the trim in the Oceanly Performance solution, a ship can carry a larger payload.

Control Room

The Oceanly Control Room is an enhancement of the data collection for real-time monitoring. Our solution offers a wide range of tools that support the Control Room concept with Fleet view dashboards and wallboard capabilities that also allows the user to run customized dashboards outside the application.

Alarms

Emissions Management

Our solution handles:

Analytics

Knowing what data to focus on and turning that into actionable insights remains a key challenge.

Route Optimization

The Oceanly Route Optimization tool allows the user to optimize routes by using forecasted data on sea conditions and weather. Our solution also take into account the ship's current location, destination, and cargo to calculate the most efficient route. Performance use advanced algorithms and machine learning techniques to build a model for predicting the most efficient route.

Overall, route optimization is a crucial aspect of modern shipping that helps companies reduce costs and improve safety. With the help of Oceanly Performance, the user can optimize routes in real-time, enabling them to make quick decisions and respond to changing conditions.

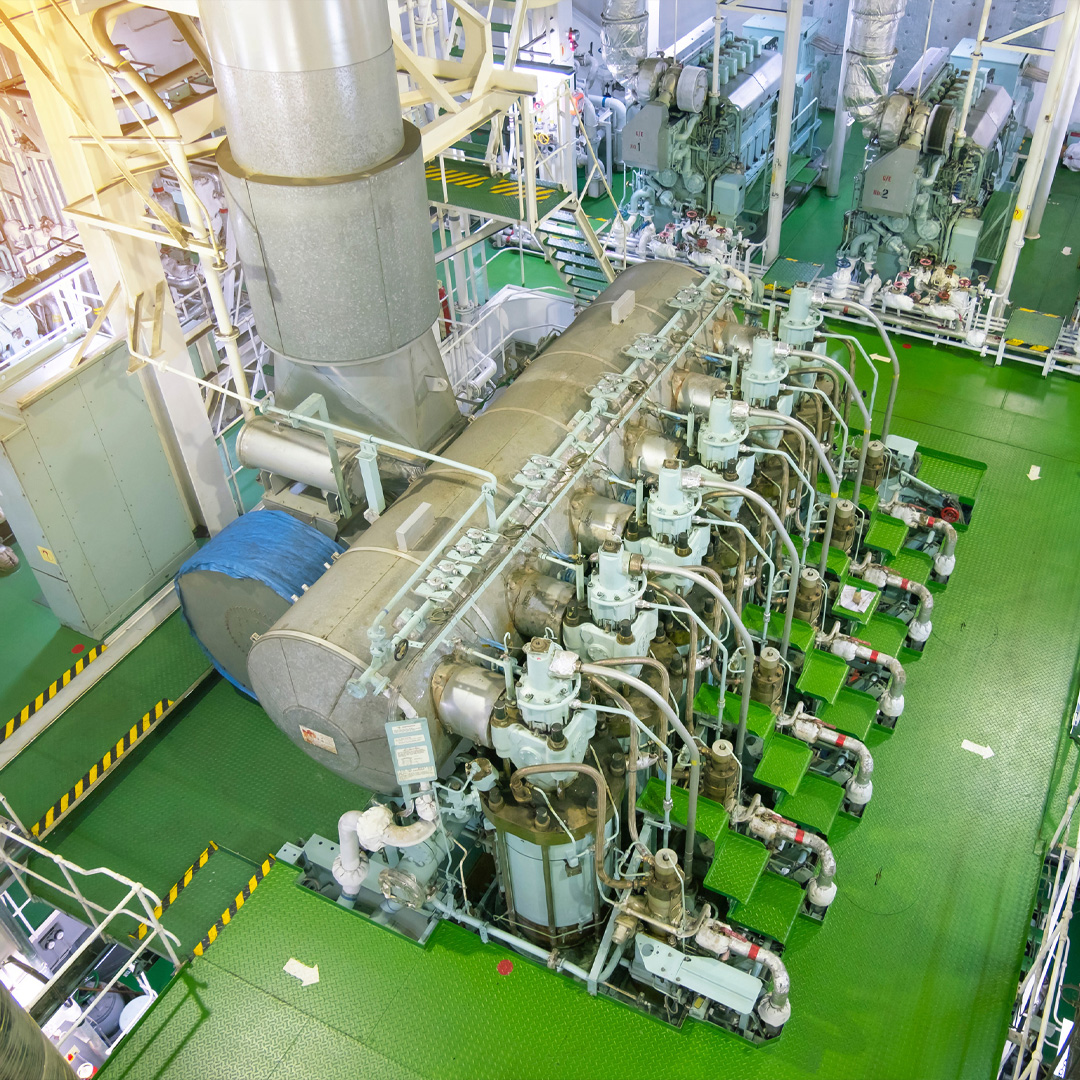

LNG & Green Fuel Manager

Oceanly Performance is fuel-agnostic and caters for all fuel-types – including zero emission fuels and bio-blends. In the solution the user can monitor all the parameters related to the different fuel systems, and compare to see the benefits and, the differences between one type of fuel to another.

LNG Tools

-

01Heel Calculator

-

02Emergency Departure

-

03Rollover Prevention

-

04Composition Calculator (Q4 2024)

-

05BOG Optimization (Q4 2024)

-

06Sloshing Alerting (Q4 2024)

Intervention Effects

Engines

Intervention Effects

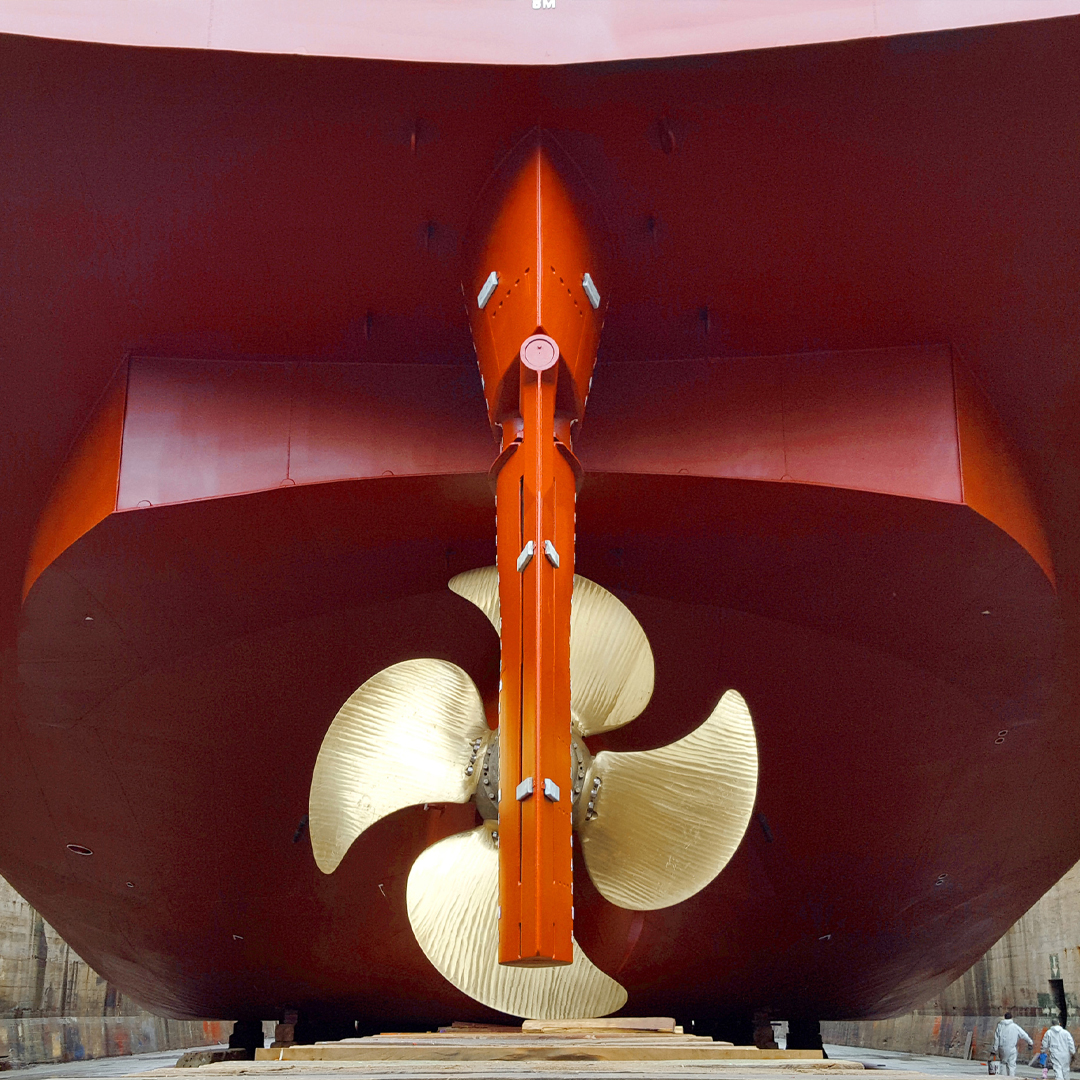

Hull and Propeller